Indicators, wheel nut locks and maintenence

HGV wheel detachment is still a huge issue in the UK. When a wheel separates from a moving truck, van, bus, coach, or trailer, it can travel at speeds up to 93mph. With a combined weight of up to 110kg, a steel wheel and tyre carry the mass of around 40 bricks. On impact, the force generated can be as much as 10 tonnes — enough to cause devastating damage.

The last report from the government suggested there were between 150 and 400 wheel detachments within the UK each year. A shocking number considering the preventable risks. Tragically, several of these incidents lead to fatalities, and many more result in life-altering injuries. The reality is that failing to secure your wheels isn’t just neglect, it’s gambling with lives.

Wheel nut loosening is a serious safety issue that can lead to wheel detachment on commercial vehicles. Understanding why it happens starts with the relationship between torque and clamping force, and how they behave under real-world conditions.

Torque vs Clamping Force: What’s the Difference?

Torque is the rotational force applied to tighten a nut or bolt. It’s what you apply using a torque wrench or torque gun.

Clamping force is the result - it’s the tension that pulls the wheel and hub together and keeps everything securely fastened.

Think of torque as the action, and clamping force as the outcome.

The goal is to apply just the right amount of torque to stretch the stud enough to generate strong, even clamping force — without overloading the threads or damaging the hardware.

Why Torque Alone Isn’t Enough

Relying only on torque can be misleading. Several factors affect how much clamping force is actually achieved:

That’s why re-torquing after initial fitment is so important - especially after the first 50–100km of driving.

Causes of Torque Loss & Clamping Force Reduction

Several mechanical and environmental factors can cause wheel nuts to loosen over time:

Always torque wheel nuts using a calibrated torque wrench and to the manufacturer's recommended settings. Over torquing can over stretch studs or crush mating surfaces. Under torquing won't create enough clamping force.

Once a wheel nut has been torqued, it must then be retorqued after 30-100 km. This is important because after some time on the road, the wheel nuts will settle into place, which can cause the clamping force to drop. Checking the torque at this point ensures everything stays tight before a long haul trip.

Then, build regular toque check routines into your regular maintenance schedule. This is especially important for fleets that do a lot of miles, vehicles that endure rough terrains, or after any wheel removal.

Use the correct torque pattern - often a star or criss-cross pattern. This ensures even clamping across the wheel.

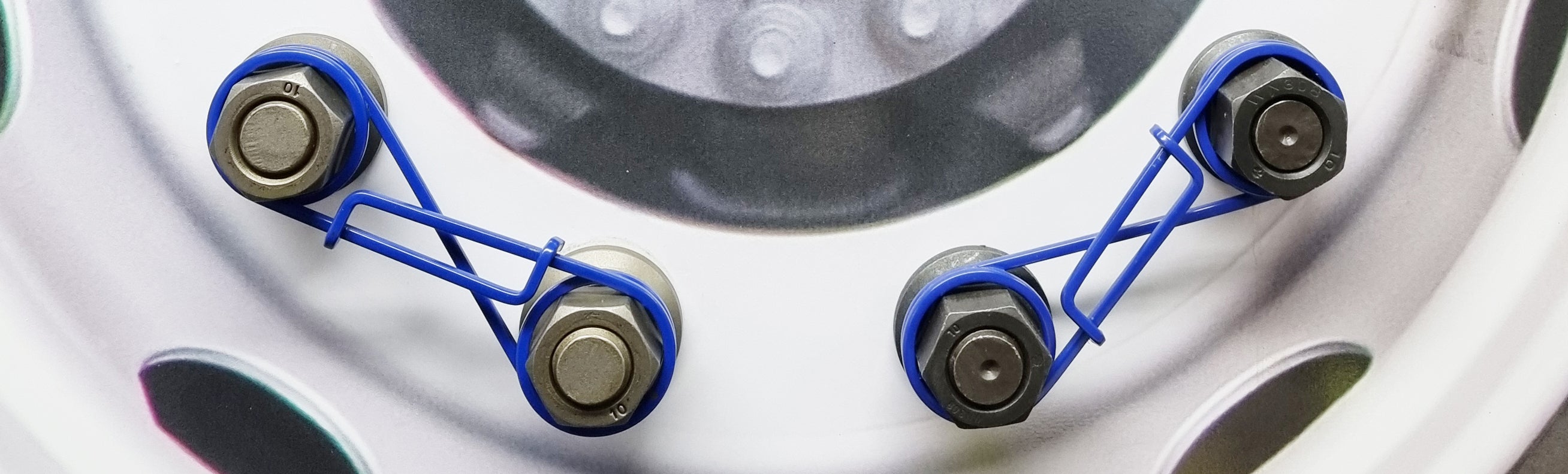

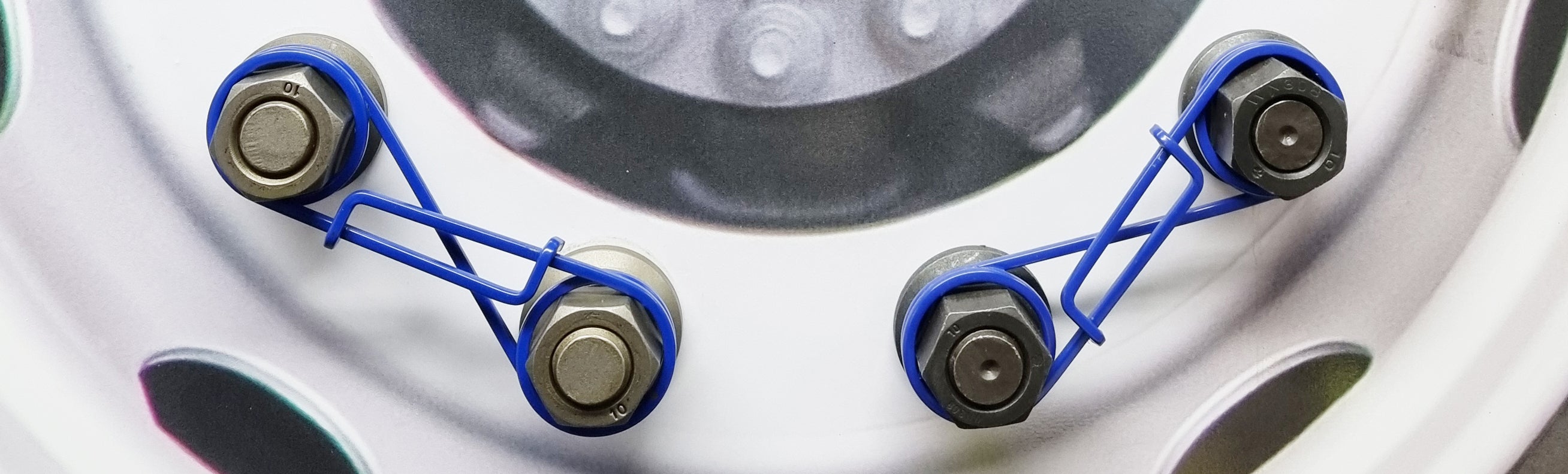

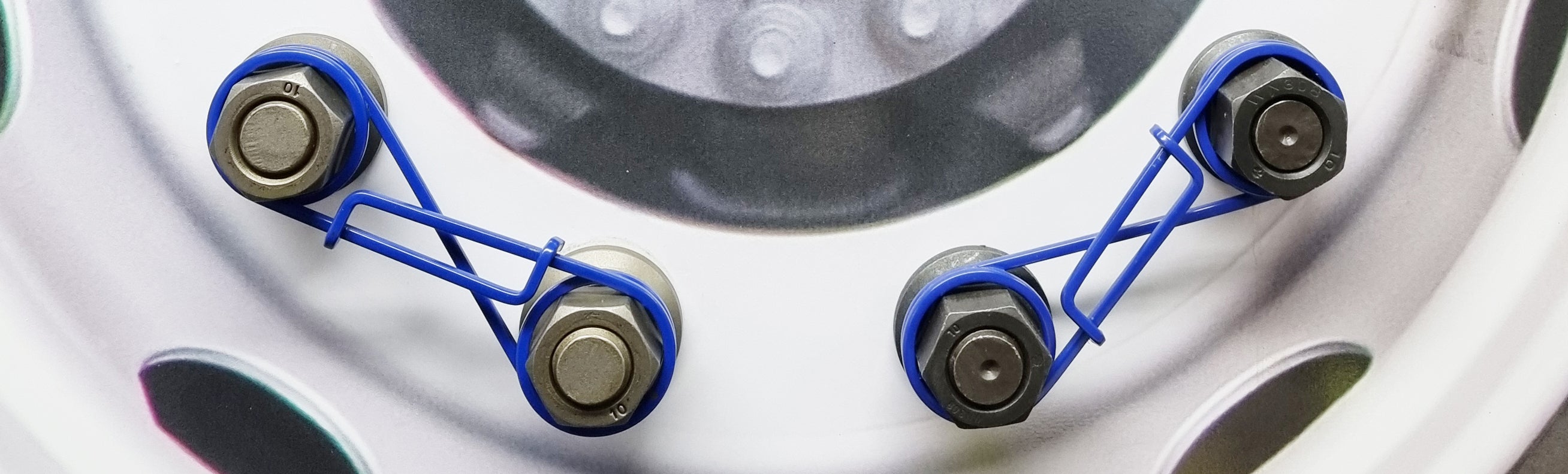

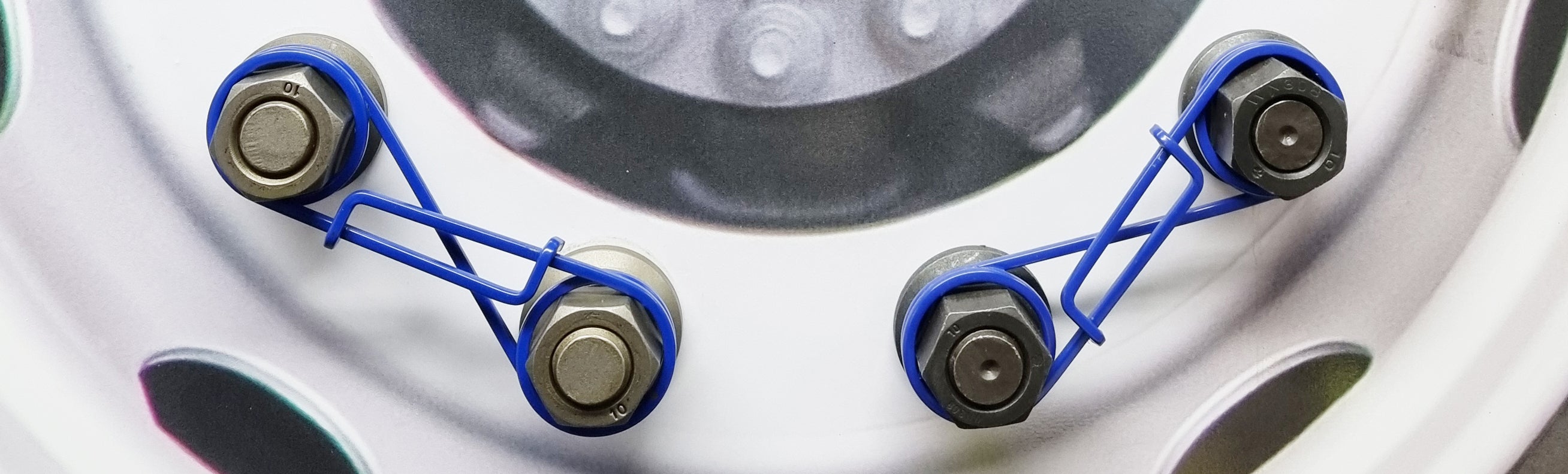

Wheel nut indicators are a visual tool to highlight movement of a wheel nut. Should a wheel nut loosen and move, the indicator will show this movement. Typically placed facing each other, so that when there is movement it's easy to spot. These indicators have become a key part of many driver walkaround checks, as it's easy to see.

There are several types available, so there is an option for every wheel type. These include flat indicators, short reach indicators and long reach indicators. Some of these are compatible with wheel trims for ultimate styling and safety, and and some are compatible with wheel nut locks such as Zafety and Prolock.

It's important to know that these indicators do not prevent wheel nuts losing torque, only shows when the nut is loose.

To figure out which is best for you, go to our guide on how to choose a wheel safety device;

Even with proper torque procedures, wheel nuts can loosen over time due to road vibration, thermal cycling, and surface movement. Wheel nut locks are a physical prevention technique. Wheel nut locks physically clamp across two adjacent wheel nuts to prevent the rotation and resist the forces that can lead to the wheel nuts loosening. While indicators only show when the wheel nuts are loose, wheel nut locks do just that - physically lock them in place.

For example, we stock Prolock, Zafety Lug Lock and Ric Clip wheel nut locks to name a few - all of which use methods of clamping on a wheel nut and locking them in place with the nut opposite.

Using wheel nut locks adds a layer of security between torque checks and visual inspections, which can only happen once the vehicle is stationary. These, on the other hand, offer protection and prevention even during the journey. If you're deciding whether to choose indicators or wheel nut locks, we would always suggest the nut locks as these are a more secure preventative measure.

While wheel nut locks physically hold wheel nuts in place during operation, indicators serve a different, but equally important, purpose. When used together, these two systems form a comprehensive wheel security solution. Locks such as Prolock or Zafety Lug Lock clamp over adjacent wheel nuts to prevent movement caused by road vibration, thermal cycling, or surface settling.

Locks prevent movement - acting as a mechanical safeguard to stop wheel nuts from rotating. Indicators reveal movement - offering a quick visual check to identify when something might be wrong. Together, they reduce risk - improving both active security (locks) and early warning systems (indicators). This supports inspection routines - ideal for operators required to carry out regular checks under DVSA guidance.

Many locks and indicators are designed to work together allowing you to clamp the nuts securely while still monitoring them visually. This layered approach is widely adopted across commercial fleets and is particularly effective in preventing wheel loss incidents.

High temperatures around the wheel can be an early warning sign of serious problems - it could be a sign of dragging brakes, failing bearings, or excessive friction due to overtightened components.

When temperatures rise beyond normal operating levels, materials expand. This thermal expansion and contraction cycle can:

But how do we know when a wheel is too hot? Especially when it happens during transit? Parma’s Hot Spot Markers provide a simple, effective way to monitor temperature changes and catch these problems early. Our Hot Spot Markers are self-adhesive stickers that change colour when exposed to high temperatures. Applied directly to the wheel hub, these stickers turn from clear to orange once the hub exceeds 180°C, indicating potential wheel issues. The colour then remains orange until replaced, so even after the journey it can be seen that there was an overheating incident, prompting investigation.

Wheel nut loosening remains one of the most serious (and preventable) safety risks for commercial vehicles. By understanding the causes of torque loss and clamping failure, operators can take smarter steps to keep their fleets secure on the road.

At Parma Group, we believe safety shouldn't be left to chance. That’s why we offer a full range of proven products - from Prolock wheel nut locks and Propoint indicators, to Hot Spot Markers and fitting tools - designed to help you build a complete, visual, and mechanical safety system. Whether you’re managing a fleet of HGVs or running a single vehicle, combining regular torque checks with mechanical locking, visual indicators, and temperature monitoring provides the best defence against wheel loss. Explore our full range of wheel safety solutions and take the next step toward smarter fleet maintenance.